Greater Efficiency in Noodle Production

Vacuum solution reduces maintenance and operating costs in noodle production

The digital magazine offers news, insights, trend reports, interviews and background information on current themes of the foodtec industry. Once a month, new specialised content with changing focal points will be published. The focus is thereby on the main themes of Anuga FoodTec.

Vacuum solution reduces maintenance and operating costs in noodle production

How food processing companies can use heat pumps to reduce their energy costs, achieve climate targets and remain competitive in the long term.

The use of heat recovery systems promises both financial and ecological benefits for the food industry.

International FoodTec Award 2027: Register now for the leading innovation award in international food technology

Alternative proteins are a growing market segment. There are over 120 companies around the world that rely on different fermentation processes.

Dynamic microfiltration with AI support for the cost-effective recovery of secondary yeast streams in breweries

Optimization of recyclable and recycled packaging systems using artificial intelligence

The EEASY lid is an aluminium lid for preserving jars that reduces the vacuum seal by simply pressing a button on the lid.

Manufacturers of packaging machines are paving the way for more sustainable food packaging with innovative solutions.

UV-C systems ensure hygienic safety of air, water, and surfaces – without the use of chemicals and in compliance with relevant standards.

TOMRA's Foreign Material Identification (FMID) solution uses artificial intelligence and cloud technology in real time.

Cooperation between WHO and BfR will increase food safety in an era of global commodity flows and improve the nutrition of people around the world.

Siemens sustainably improves machine maintenance at Sachsenmilch with AI-supported prediction algorithms

Interview with Marielle In de Braek about condition monitoring with OPTIME from Schaeffler: Hygienic, retrofit-friendly, and efficient against downtime.

Robot-aided automation and gripping technology are becoming increasingly important in the food industry.

KUKA demonstrates how modern robotics solutions combine skilled labour shortages, hygiene requirements and increased efficiency in palletising.

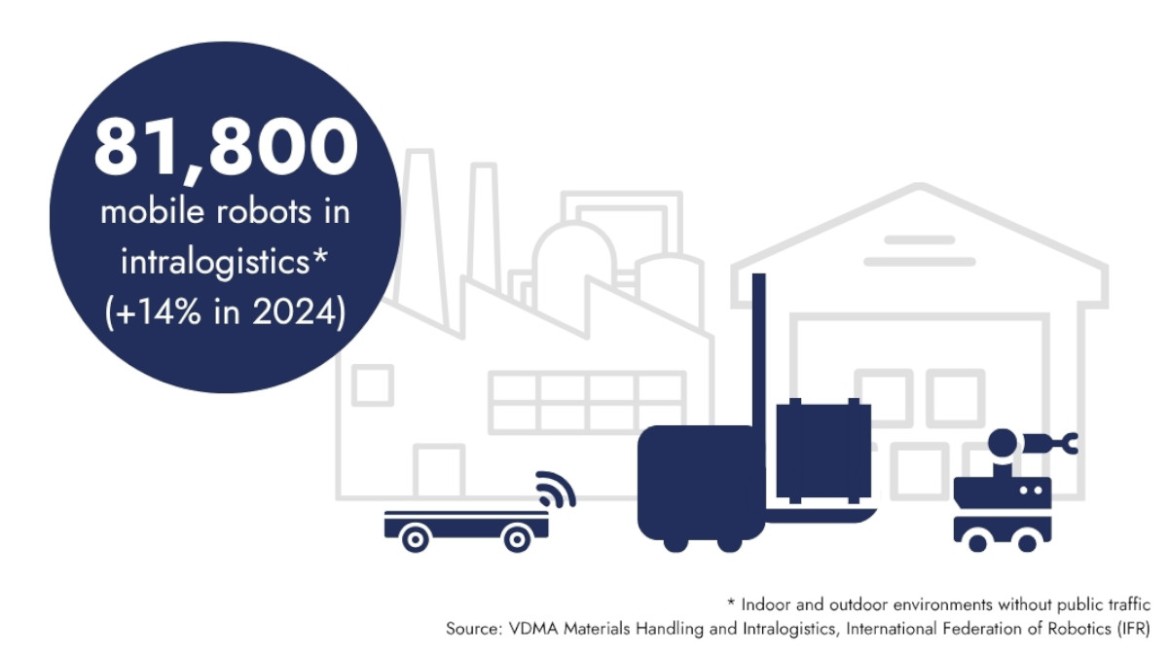

According to “World Robotics 2025 – Service Robots,” sales of mobile robots in intralogistics are increasing worldwide.

Accelerate processes, save energy and sustainably increase operational efficiency in deep-freeze warehouses with automation, AI and robotics.

The SuperSustain international research project is investigating how supermarkets can promote sustainability in consumption and production.

Yeastup AG extracts vegan proteins for human nutrition from brewery by-products in a sustainable circular process.

Which of today's trends have the potential to influence the food sector in 2035, and what might this look like?