Protein Shifting by Dry Fractionation

In order to increase the protein content of wheat and legumes, Hosokawa Alpine has developed the process of protein shifting by dry fractionation.

Processing

In order to increase the protein content of wheat and legumes, Hosokawa Alpine has developed the process of protein shifting by dry fractionation.

Innovative technologies and ingredients for coatings with optimum adhesion, a long-lasting crunch effect and trend-oriented recipes.

The refinement of powders by means of granulation, agglomeration, micro-encapsulation and coating creates high-quality products with functional properties.

Modern foreign body detection technologies such as X-ray scanners and metal detectors ensure food safety and quality in production.

Aseptic technologies play an essential role in the production of hygienically sensitive foods such as baby food or dairy products.

Dealcoholised wines are produced using an optimised variant of classic vacuum distillation, i.e. vacuum rectification.

The KSL horizontal slicer for fresh meat offers extreme precision in slice thickness and max-imum efficiency.

The twin-screw extruder with innovative dynamic cooling nozzle from Clextral enables meat and fish substitute products with a realistic texture.

High-pressure pasteurisation is gaining in importance and offers an interesting alternative to conventional heat treatment for sensitive products.

KRONEN is granted a patent for tools and processes that use robots to pit and peel avocados.

Additive manufacturing is becoming increasingly important in systems and mechanical engineering for the food industry and provides greater freedom of design.

Alternative proteins are a growing market segment. There are over 120 companies around the world that rely on different fermentation processes.

Lyras A/S has developed a non-thermal pasteurisation process based on UV technology that is also suitable for unclear liquids.

Plant-based flours are becoming increasingly important as the basis for many new recipes, and with them the specialists for bulk materials technology.

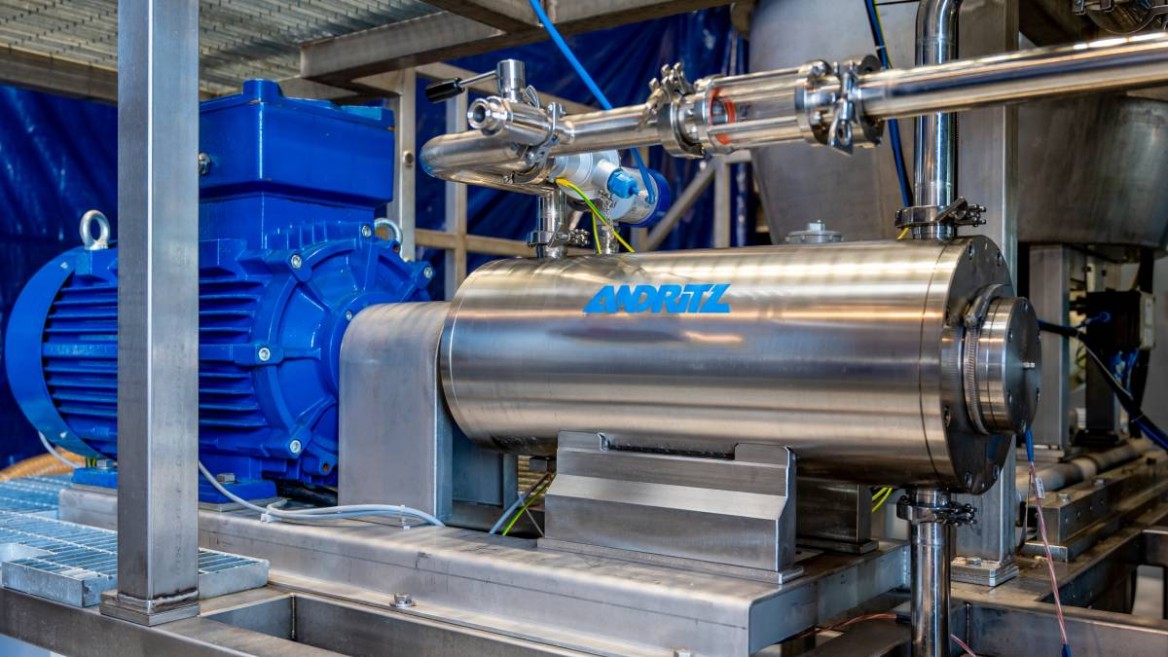

Dynamic microfiltration with AI support for the cost-effective recovery of secondary yeast streams in breweries

The ProFry industrial fryer system from Gea sets new technological standards with its patented, automatic inline oil measurement.

New technology for cavitation extraction in the counter-current area – efficient extraction impresses experts from the food industry.

Raw material selection, processing and extruder technology are crucial for authentic taste, texture and bite in vegan meat alternatives.

Digital B2B trading platforms offer producers the option to reduce surpluses and keep food in the circulation.

The demands on seals are high, resulting from the numerous and extremely diverse applications.

The goals of minimal processing require food to be processed only minimally, i.e. less or with shorter processing steps.

The extrusion of starch and protein-based food and feed has the potential to make a significant contribution to a sustainable supply

GEA can use its mobile test center to test pilot processes for producing New Foods on a commercial scale.

Demand for alternative proteins is higher than ever before. Their use offers a variety of options for new products ...

Aseptic technologies play an essential role in the production of hygienically sensitive foods such as baby food or dairy products.

The growth market for mycoproteins is characterised by low processing and high nutritional value.

Schubert & Salzer Control Systems achieves particularly high-volume flows with the world's first three-way ball sector valve.

Innovative coextrusion systems enable the production of plant-based meat alternatives with optimised texture, flavour and sustainability.

Innovative extrusion systems enable the efficient production of plant-based meat alternatives with a convincing flavour.

Vacuum expert Schmalz has acquired the mGrip Finger Gripper product family from the US company Soft Robotics Inc.

Processing protein powders to an optimum quality is challenging. It is achieved using the vacuum expansion process.

Anticaking advances help the food industry to cut its losses in a safe way and households to reduce food waste

_1200x675_m24_full_m36_641_1024.png)

The ENORM Biofactory in Denmark utilises the efficiency of the black soldier fly and the precision of hygienic oil robots from KUKA.

Klüber Lubrication stands for professional lubricant management as an essential part of risk assessment.

EnWave's REV technology is versatile and can process a wide range of foods.

As a specialist for end-to-end meat processing, Handtmann offers flexible, modular cutting-edge technology for every production step.

Microalgae are considered the protein source of the future. However, process costs need to be reduced further and cultivation methods optimised.

The BladeStop safety bandsaw increases safety and reduces the risk of serious injury by stopping the blade in a fraction of a second.

The GEA vaculiq vacuum spiral filter sets the highest standards in the field of industrial juicing of food and beverages.

A mobile screw pump specially developed for the food industry conveys viscous products to their destination gently and with low pulsation.